Our Products

|

M Pump is an Air Operated Double Diaphragm manufacturing company based in Malaysia with more than 30 years of professional & technical experience in Air Operated Double Diaphragm pump. Our pumps are manufactured and assembled locally here in Malaysia.

M Pump is designed for Adhesive Coating, Ceramic, Chemical, Construction, Electrical & Electronic, Food Processing, Marine, Mining, Oleo Chemical, Oil & Gas, Paint, Printing, Pulp & Paper, Recycling, Rubber & Latex, Petro Chemical, Semi-Conductor, Shipbuilding and Repair, Waste Water and many other industries. |

| |

|

|

| |

01

Polypropylene Pump

|

| |

- Material: Polypropylene

- Pump range: 1/4" to 2"

- Flow Rate: up to 650 L/min [171.70 gpm]

- Max Working Pressure: 125 psi [8.26 Bars]

|

|

.png) |

|

02

Kynar / PVDF Pump

|

| |

- Material: Kynar / PVDF

- Pump range: 1/4" to 2"

- Flow Rate: up to 650 L/min [171.70 gpm]

- Max Working Pressure: 125 psi [8.26 Bars]

|

|

|

|

03

Aluminium Pump

|

| |

- Material: Aluminium

- Pump range: 1/2" to 3"

- Flow Rate: up to 950 L/min [250.96 gpm]

- Max Working Pressure: 125 psi [8.26 Bars]

|

|

|

|

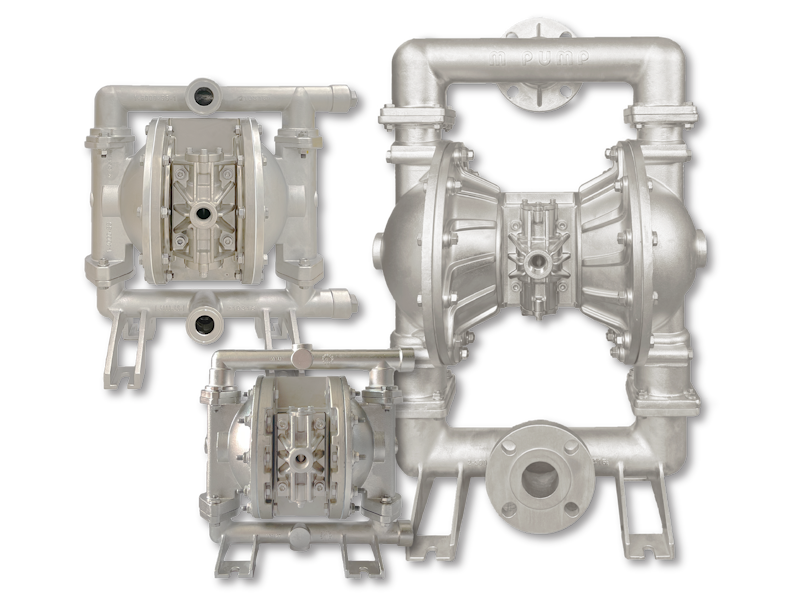

04

Stainless Steel Pump

|

| |

- Material: Stainless Steel

- Pump range: 1/2" to 3"

- Flow Rate: up to 950 L/min [250.96 gpm]

- Max Working Pressure: 125 psi [8.26 Bars]

|

|

|

|

05

FDA Food Processing Pump

|

| |

- Material: Stainless Steel

- Pump range: 1/2" to 3"

- Flow Rate: 950 L/min [250.96 gpm]

- Max Working Pressure: 125 psi [8.26 Bars]

|

|

|

|

| |

Product Range

|

| |

|

|

| |

|

|

|

|

|

Characteristic

|

| AIR OPERATED DOUBLE DIAPHRAGM PUMP |

| |

| Revolutionize your pumping systems with our high-efficiency diaphragm pump. M Pump is designed for peak performance, while minimizing wear and maximizing efficiency. Cut costs, reduce environmental footprint, and experience unmatched reliability in industrial, chemical, and pharmaceutical applications. Join us in leading the way toward more efficient, productive, and sustainable solutions. Upgrade to the future of fluid handling with M Pump now! |

| |

| With our patented and award-winning design, M Pump has firmly established ourselves as a frontrunner in efficiency within the Air Operated Double Diaphragm Pump industry. Our innovation is not just a leap forward; it's a game-changer. By setting new standards for energy utilization and operational reliability, we take pride in delivering unparalleled efficiency, a critical factor in today's competitive landscape. |

| |

| The design simplicity of M Pump translates to fewer components and moving parts compared to our competitors. Our streamlined design provides a notably cost-effective regime. Furthermore, M Pump's straightforward and user-friendly design ensures that maintenance remains accessible and efficient, thus extending its appeal, even to non-technical personnel with little experience. |

| |

.jpg) |

| |

| Additionally, the sealless design of AODD pumps make them ideal for environments where the leakage of highly corrosive liquids would pose significant environmental risks. The diaphragm within the system serves as a highly effective barrier, ensuring that the transferred liquid remains uncontaminated throughout the process. In the event of a diaphragm failure, rest assured that the AODD pump automatically halts operations, containing the liquid within the system and mitigates environmental risks. Additional leak detection equipment are available upon request. |

| |

| M Pump is not only self-priming and sealless but also excels in handling abrasive, corrosive, and shear-sensitive liquids laden with particles. By selecting the appropriate material for the pump body and elastomer, virtually all pumping problems find their solutions. High viscosity requirements will not be an issue, AODD pumps are designed to deliver significant discharge pressure under such demanding conditions. |

| |

| Safety is of paramount importance, and here, the AODD pump truly shines. As an air-operated system, it is inherently explosion resistant, ensuring operational integrity even in hazardous environments. When electrical power is unavailable or poses safety concerns, AODD pumps emerge as a dependable alternative. |

|

|

|

Materials and Options

|

.png)

Wetted Materials

- Aluminium

- Stainless Steel

- Polypropylene

- Kynar® (PVDF)

- Cast Iron

|

|

|

.png)

Non-Wetted Materials

- GFPP

- Aluminium

- Stainless Steel

- Nickel Plated

|

|

|

| Diaphragm Options |

|

|

- Hytrel

- Santoprene

- Polyurethane

|

|

|

| Valve Ball Options |

- Buna

- Neoprene

- PTFE

- Stainless Steel

|

- Hytrel

- Santoprene

- Polyurethane

|

|

|

|

|

|

| Pump Advantages |

|

Compact Size |

|

Self Priming |

|

Air Operated |

| |

| Wide variety of construction and elastomer options available |

|

Can run at a variety of flows |

|

Pressure can be adjusted infinitely |

|

Can run dry without damage |

| |

| Low product degradation and agitation |

|

Can handle some solid content |

|

Can operate submerged |

|

Does not generate heat |

| |

| Can be installed outdoors indefinitely |

|

Simple in operation |

|

No mechanical seals |

|

Easily maintained with no special tools or skills required |

|

|

|

Chemical Resistance Chart

|

| Download Chemical Resistance Chart |

|

|

Temperature Limitations

|

| Compound |

Optimum Temperature |

Main Applications / Chemical Compatibility |

| Neoprene |

10 to 54°C

50 to 130°F |

General purpose diaphragm (non agressive applications -- water-based slurries, well water or sea water--). |

| Buna-N |

10 to 60°C

50 to 140°F |

Petroleum/oil-based fluids (leaded gasolines, fuel oils, non-synthetic hydraulic oils, kerosene, turpentines, motor oils). |

| Polyurethane |

10 to 54°C

50 to 130°F |

Non-aggressive applications (water-based slurries, well water or sea water). |

| Santoprene |

10 to 100°C

50 to 212°F |

Low cost alternative to Teflon® in many acidic and caustic applications such as sodium hydroxide, sulfuric or hydrochloric, at a cost comparable to Neoprene. |

| Hytrel |

10 to 54°C

50 to 130°F |

FDA approved for food processing applications, outstanding general purpose diaphragm as well. |

| PTFE |

10 to 180°C

50 to 356°F |

Aggressive chemicals and solvent but low abrasion resistance. |

|

| |

| Temperature limitations are based on the mechanical stress only. Certain chemical will significantly reduce the maximum safe operating temperatures. Consult M Pump (info@m-pump.net) for chemical compatibility and temperature limits for specific fluids. |

|

| |

| Request A Quote |

|